Amazon’s deployment of its 1 millionth warehouse robot is more than a company milestone—it’s a signal of a paradigm shift in global supply chain and logistics operations. By integrating advanced robotics and generative AI, Amazon is setting a new industry standard for speed, scalability, and labor efficiency.

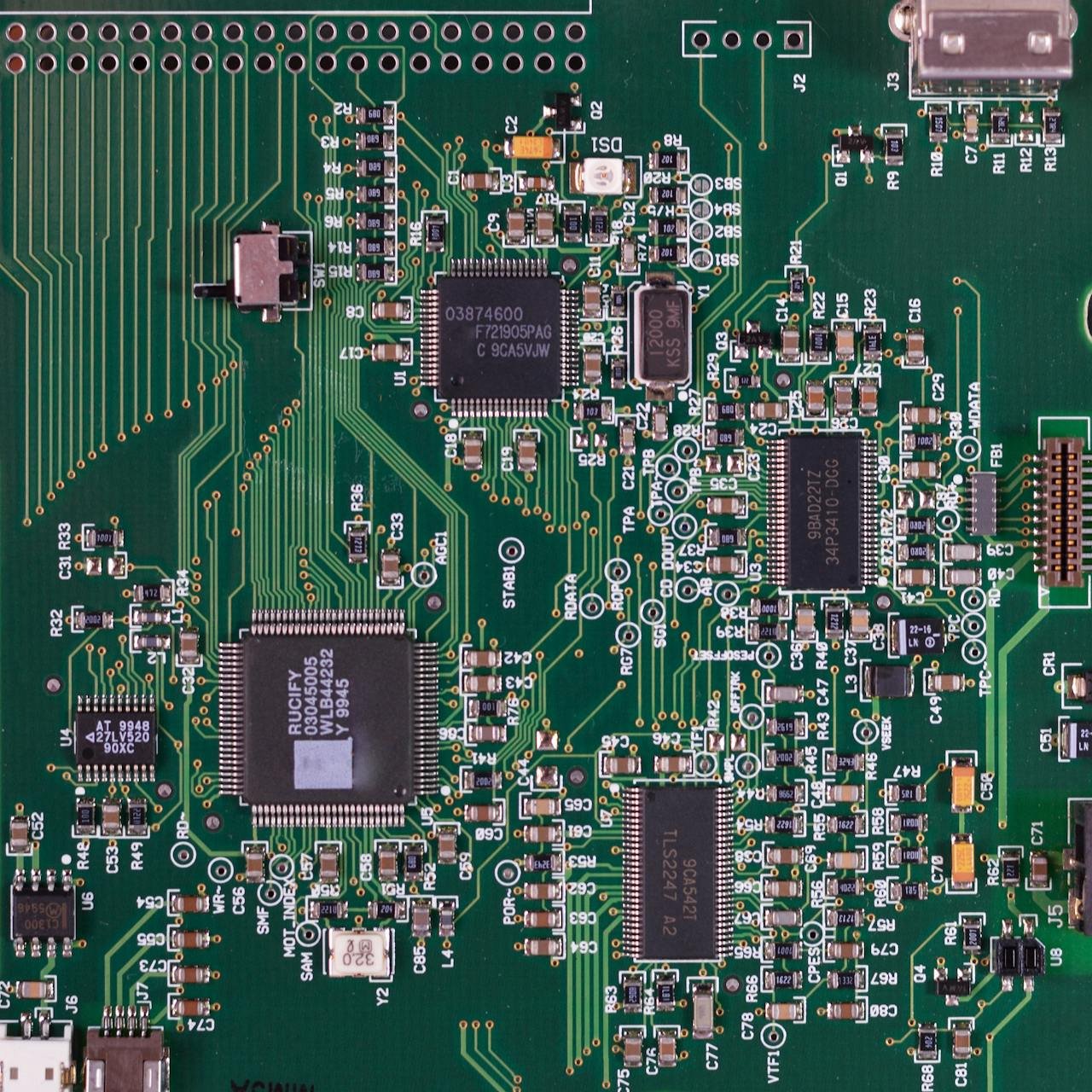

The backbone of this transformation is DeepFleet, Amazon’s generative AI platform that orchestrates thousands of robotic units in real time. DeepFleet’s ability to dynamically reroute robots, minimize warehouse congestion, and optimize energy use reflects a new class of intelligent logistics infrastructure.

With 75% of all Amazon deliveries now involving robotic systems, traditional logistics providers are taking notice. Industry giants like FedEx, UPS, and JD Logistics are accelerating their own automation programs to stay competitive. The success of Amazon’s AI-robot integration offers a template for others to follow—but it also sets a bar that may be out of reach for smaller players with limited R&D budgets.

Amazon’s scale allows it to roll out automation not just as an efficiency tool, but as a logistics differentiator—shorter delivery times, reduced costs, and a leaner fulfillment workforce. Experts suggest this milestone could lead to an industry-wide restructuring, where companies must either innovate quickly or face declining relevance.

Moreover, regulatory bodies are beginning to weigh in, concerned about monopolistic advantages, labor displacement, and ethical questions around AI in essential services. The U.S. and EU have both hinted at future oversight of mass automation in logistics.

In sum, Amazon’s 1-million robot milestone is not merely about quantity—it’s about changing what is operationally possible in logistics. The future of delivery will not be shaped in warehouses alone, but by code, data, and the speed of AI.